In Stock

Elevator Overhead Height

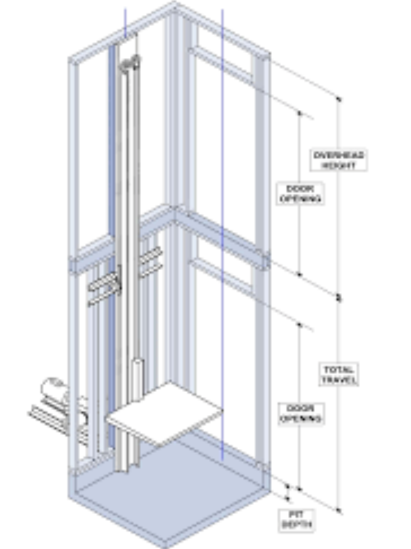

Elevator overhead height refers to the space between the top of the elevator cabin and the shaft ceiling, accommodating essential components like counterweights, pulleys, and safety buffers. The required height varies based on building specifications and elevator type, ensuring smooth operation, proper ventilation, and compliance with safety regulations.

Elevator Overhead Height

Elevator overhead height is a crucial factor in the design and installation of an elevator system. It refers to the vertical distance between the top of the elevator cabin and the ceiling of the elevator shaft. This space is necessary to accommodate essential mechanical components such as counterweights, pulleys, suspension cables, and safety buffers. Proper overhead height ensures smooth operation, safety compliance, and efficiency in an elevator’s performance.

Factors Affecting Overhead Height

The required overhead height varies depending on the type of elevator, its speed, and its intended use. In a standard residential or low-rise commercial elevator, the overhead height typically ranges from 10 to 14 feet. However, high-speed elevators in skyscrapers or commercial towers require significantly greater overhead space to house advanced lifting mechanisms, control systems, and emergency safety features. The height must also accommodate movement clearance, ensuring that the elevator can stop safely without hitting the ceiling in case of mechanical failure.

One of the key factors influencing elevator overhead height is the type of drive system used. Hydraulic elevators, which are commonly found in low-rise buildings, generally require less overhead space because their lifting mechanism relies on a piston system rather than counterweights and cables. In contrast, traction elevators, including those with gearless motors, require additional overhead space for sheaves, braking systems, and hoisting machinery. Machine-room-less (MRL) elevators have helped reduce the required overhead height compared to traditional traction systems, as their compact motors are installed within the shaft itself rather than in a separate machine room.

Safety Considerations in Overhead Height

Overhead height also plays a role in emergency safety features. Modern elevators are equipped with emergency buffer zones to prevent collisions if the cabin travels too far beyond the top floor. The overhead clearance allows space for shock absorbers, limit switches, and counterweight systems to function correctly. Insufficient overhead height can pose serious risks, leading to operational inefficiencies or even dangerous situations in the event of an emergency brake activation.

Regulatory Requirements for Overhead Height

Regulatory standards and building codes dictate the minimum overhead height for elevators to ensure safety and functionality. Organizations such as the American Society of Mechanical Engineers (ASME) and the European Committee for Standardization (CEN) set international guidelines for elevator construction, including required clearance space for overhead components. Developers and architects must comply with these regulations to ensure that the elevator system meets global safety standards.

Modern Innovations and Overhead Height

The modernization of elevator technology has influenced overhead height requirements in recent years. Advances in compact motor designs, energy-efficient counterweights, and AI-driven control systems have allowed for reduced overhead space while maintaining high levels of performance. However, the fundamental need for adequate clearance remains essential for smooth operation and long-term reliability.

Reviews

There are no reviews yet.